DLT Engineering

Product Page

Product Page

DLT Skidding systems

DL-SU and DL-GP skidding system

DL-SU jacking and skidding systems.

Our DL-SU lift and skid units combine a vertical ram to support the load and a horizontal ram to move the load along a skid track. We offer DL-SU units with load carrying capacities from 200 - 2500 tonnes per unit and jacking heights of 60m or more using modular steel jacking cans. We design and supply the complete system, including hydraulic power packs, track and computer control system. The DL-SU systems can be used for lifting and skidding of any heavy object, and are typically used for jacking and load out of offshore platforms, bridge decks, heavy steel fabrications and heavy machinery. Our computer control system continuously monitors the load in each jack and will automatically correct the jack strokes during skidding to maintain the required load distribution, thus removing the need to link the support

DL-SU jacking and skidding systems.

Our DL-SU lift and skid units combine a vertical ram to support the load and a horizontal ram to move the load along a skid track. We offer DL-SU units with load carrying capacities from 200 - 2500 tonnes per unit and jacking heights of 60m or more using modular steel jacking cans. We design and supply the complete system, including hydraulic power packs, track and computer control system. The DL-SU systems can be used for lifting and skidding of any heavy object, and are typically used for jacking and load out of offshore platforms, bridge decks, heavy steel fabrications and heavy machinery. Our computer control system continuously monitors the load in each jack and will automatically correct the jack strokes during skidding to maintain the required load distribution, thus removing the need to link the support

points hydraulically to compensate for track construction tolerances and settlements.

Our standard DL-SU200, SU333 and SU666 skidding systems have been designed to be compact, modular and flexible. Each of the three standard sizes can be linked to form a support point of double capacity as shown below. Our standard DL-SU systems can therefore be used to support the following loads per point :

Our standard DL-SU200, SU333 and SU666 skidding systems have been designed to be compact, modular and flexible. Each of the three standard sizes can be linked to form a support point of double capacity as shown below. Our standard DL-SU systems can therefore be used to support the following loads per point :

- DL-SU200 : 200 te and 400 te per support point

- DL-SU333 : 333 te and 666 te per support point

- DL-SU666 : 666 te and 1332 te per support point

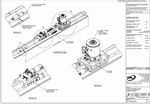

DL-SU in single configuration

DL-SU in single configuration DL-SU in double configuration

DL-SU in double configurationDL-GP skidding systems

Our DL-GP skidding systems are designed to push and pull very heavy loads in both onshore and offshore environments. They walk along a skid track using anchor plates to engage with slotted holes in the top of the skid track.

Our DL-GP skidding systems are designed to push and pull very heavy loads in both onshore and offshore environments. They walk along a skid track using anchor plates to engage with slotted holes in the top of the skid track.

The DL-GP1000 unit shown below can self-walk in both directions and has a push and pull capacity of 1000 tonnes. It has a hydraulic load balancing system to distribute the anchor force equally to four slotted holes to reduce the cost of the skid track. 2 No DL-GP1000 units were delivered to Nippon Steel in 2012 for use on their offshore jacket installation barge. Read more»